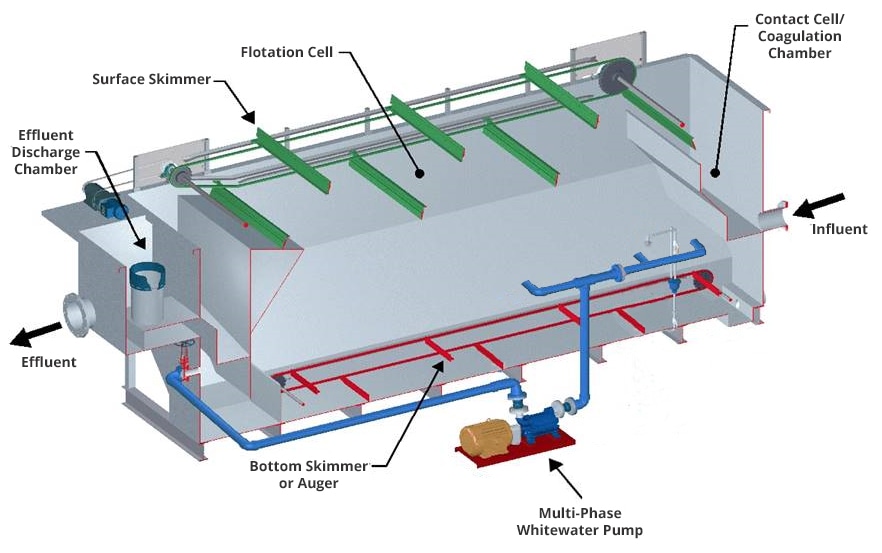

Where and Why DAF?

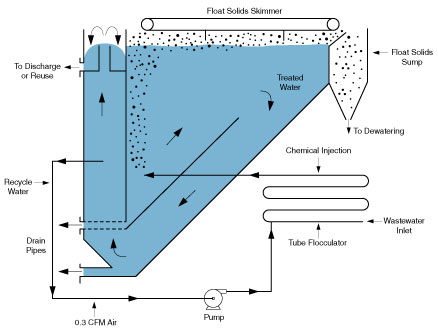

Typically, DAF is used to clarify wastewater from food processing plants, industrial laundries, oil refineries, paper mills, metal finishing, and many other niche industries so water is suitable for reuse or discharge to sewer.

- Reduced Footprint

- Lower Compliance Costs

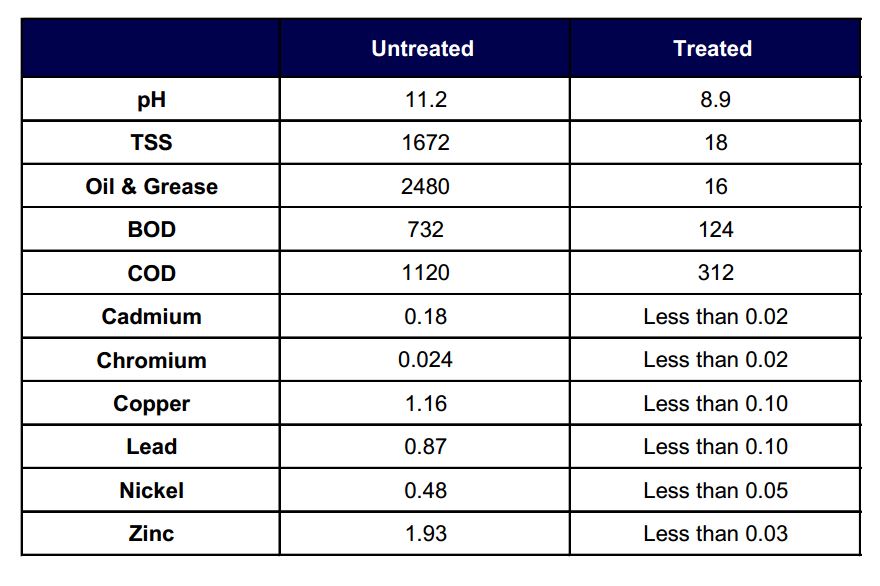

- High Efficiency

- High Quality Treated Water

- Increase Reuse Rates